1、 Physical and chemical properties of LaB6

The range of existence of lanthanum hexaboride: containing 85.8-88 (wt)% B, it is purple when containing 85.8% B and blue when containing 88% B; The density is 4.7g/cm3, the room temperature resistance is 15-27 μ Ω, the Vickers hardness is 27.7GPa, the work function is 2.66eV, and the emission constant is 29A/cm2 · K2.

Lanthanum hexaboride is opaque, appearing light reddish purple when dry and deep red when moist.

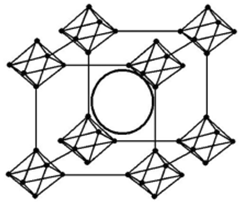

Lanthanum hexaboride has a cubic crystal structure, as shown in Figure 1:

Figure 1 Crystal structure of LaB6

The structural characteristics of cubic lanthanum hexaboride crystals can be seen from the figure:

1) Boron atoms form a three-dimensional cubic framework structure, with larger volume lanthanum atoms inside.

2) The boron framework is an octahedron, with each vertex of the cube having an octahedron formed by a boron atomic framework, which is connected to each other by vertices.

3) Each boron atom is adjacent to five boron atoms, four of which are in their own octahedron, and the other is located in the direction of one of the main axes of the cube, thus giving a homopolar lattice structure with a coordination number of 5.

4) Each boron atom has three valence electrons assigned to five bonds.

5) The coordination number of metal atoms trapped in the boron lattice is 24.

The crystal structure of borides determines a series of unique properties:

1) Due to the strong bonding force between boron atoms (lattice constant 4.145 Å), it is a refractory compound with a melting point of 2210 ℃.

2) The chemical properties are very stable and do not react with water, oxygen, or even hydrochloric acid; At room temperature, it only reacts with nitric acid and aqua regia; Oxygen will only undergo oxidation at 600-700 ℃.

3) Within a certain temperature range, the coefficient of expansion approaches zero.

4) Good stability in air, surface contamination during use can be restored by vacuum heat treatment.

5) Good resistance to ion bombardment and able to withstand high field strength.

6) Due to the absence of valence bonds between metal atoms and boron atoms, the valence electrons of metal atoms are free. So borides have high conductivity, and the resistance of lanthanum hexaboride is roughly the same as that of lead metal. The temperature coefficient of its resistivity is positive.

7) If hexaborides are brought into contact with refractory metals at high temperatures, boron will diffuse into the metal lattice and form interstitial boron alloys with the metal. At the same time, the boron framework will disintegrate, allowing the metal atoms to evaporate.

8) When borides are heated to a considerable temperature, the metal atoms on the crystal surface evaporate, but are immediately replenished by metal atoms diffusing from within the lattice, while the boron framework remains unchanged, minimizing the loss of surface active substances.

Due to the above advantages, LaB6 is made into electronic components in modern technology and widely used in civilian and defense industries: 1) electron emission cathodes. Due to the low work function of electrons, cathode materials with the highest emission current at medium temperatures can be obtained, especially high-quality single crystals, which are ideal materials for high-power electron emission cathodes. 2) High brightness point light source. Core components used for preparing electron microscopes, such as optical filters, soft X-ray diffraction monochromators, and other electron beam light sources. 3) High stability and long lifespan system components. The excellent comprehensive performance enables it to be applied in various electron beam systems, such as electron beam engraving, electron beam heat sources, electron beam welding guns, accelerators, and other engineering fields for producing high-performance components.

2、 Preparation of LaB6

(1) Preparation of LaB6 powder

1) Pure element synthesis method

This method is the initial research approach, suitable for phase diagram studies, but not suitable for practical production applications.

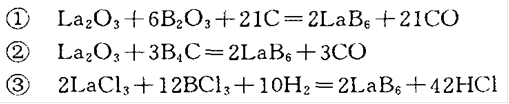

2) Synthesis of compounds containing La and compounds containing B

This method is for industrial use and has different reaction equations depending on the reactants:

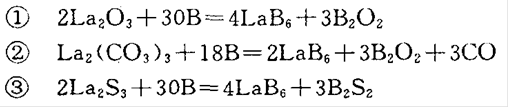

3) Compounds for reducing La with pure B

(2) Preparation of LaB6 Polycrystalline

LaB6 polycrystals are generally prepared by sintering and hot pressing methods. In situations where voids are required, sintering can only be used for preparation. Use LaB6, ZrB2 or ZrC crucible sintering. To prevent the infiltration of B, it is not advisable to use a B crucible. Usually sintered under a hydrogen atmosphere. The hot pressing pressure is 400atm, the temperature is 2000 ℃, and the holding time is 1-2 hours. The size of the billet is generally 100mm × 30mm.

(3) Preparation of LaB6 Single Crystal

At present, the preparation methods of single crystals can be summarized as zone melting method, solvent method, and gas-phase method.

1) Zone melting method

Zone melting method is the most commonly used method for preparing rare earth boride single crystals. When using LaB6 as an electrode radiation material, it is necessary to prepare high-purity single crystals. Although the exact relationship between impurities in LaB6 and its service life as an emitter electrode has not been found yet, the higher the purity of LaB6, the longer its service life. Therefore, it is meaningful to prepare high-purity materials.

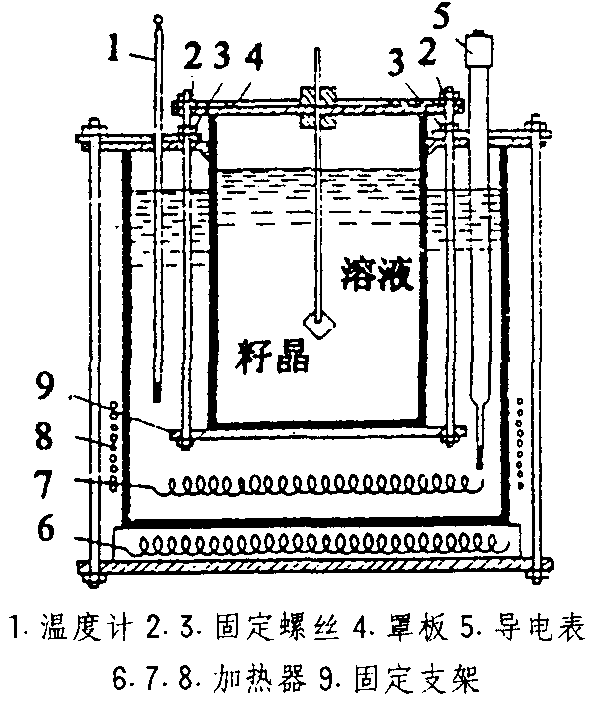

In order to prepare high-purity LaB6, a suspension zone melting method without a crucible is generally used, protected by inert gas, as shown in Figure 2:

Figure 2 Schematic diagram of zone melting method

The zone melting methods for preparing single crystals include radio frequency heating, electron beam heating, arc heating, and laser beam heating.

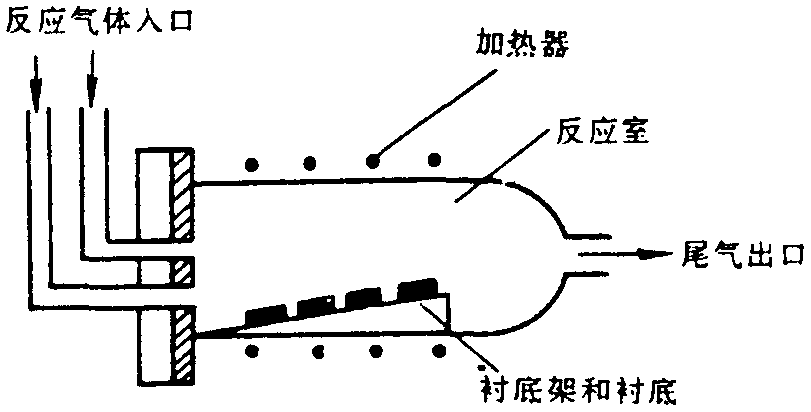

2) Solvent method

The solvent method is also the basic method for preparing single crystal LaB6, which includes aluminum solvent method and rare earth solvent method. The two are similar, except that the latter uses rare earth elements instead of aluminum. The schematic diagram is as follows:

Figure 2 Schematic diagram of zone melting method

The zone melting methods for preparing single crystals include radio frequency heating, electron beam heating, arc heating, and laser beam heating.

2) Solvent method

The solvent method is also the basic method for preparing single crystal LaB6, which includes aluminum solvent method and rare earth solvent method. The two are similar, except that the latter uses rare earth elements instead of aluminum. The schematic diagram is as follows:

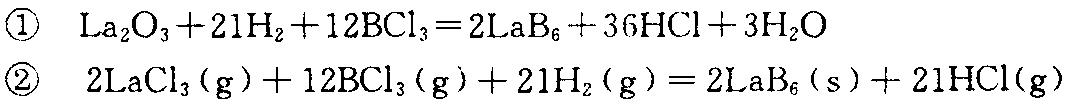

Figure 4 Schematic diagram of CVD method principle

The chemical reaction equations applicable to the production of LaB6 by CVD method are:

3、 Emission properties of single crystal LaB6 cathode

LaB6 cathode is a crystal with a special structure. Due to its excellent conductivity and low work function as a metal, it can achieve a direct current emission current of 0-100A/cm2 when operating at 1400-1680 ℃, far superior to oxide and pure metal cathodes; At the same time, it has good thermal and chemical stability.

Since the discovery that LaB6 has a low work function and low vapor pressure, making it suitable as a material for hot electron emission, people have been studying the advantages of LaB6 cathodes. Early use of sintered LaB6 was made, but it had issues with brightness and stability due to its uneven structure and high levels of impurities. These problems were solved after the development of single crystal LaB6, which has a uniform structure and high purity. Therefore, single crystal LaB6 has replaced the hairpin tungsten cathode for electron beam devices such as electron microscopes and electron exposure systems.

Research has shown that the (100) crystal plane has the lowest work function, can provide the highest current density, and has the best usage.

(1) The influence of cathode tip size

In theory, the brightness of the electron beam emitted from a hot electron gun is determined by the cathode temperature, work function, and acceleration voltage. However, the actual brightness is reduced due to emission current limitations and space charge effects. And the space charge effect depends on the field strength distribution in the electron gun space, that is, it depends on the geometric shape and size of the cathode surface, including the size of the cathode tip.

Experiments have shown that when the curvature of the tip is relatively small, the desired high brightness for low work function LaB6 can be obtained. However, during long-term working hours, the cathode with a small curvature radius only disappears after a short working time, and the small spherical surface at the tip disappears. The large curvature radius of 100 μ m can still maintain the (100) plane perpendicular to the optical axis after exceeding 1500 hours, thus providing a relatively stable emission.

(2) The influence of tip axis orientation

The anisotropy of the work function depends on the lattice structure of LaB6 crystal, therefore, the emission characteristics also depend on the crystal orientation of the cathode tip axis. It is important to select the appropriate orientation as the axis of the cathode tip in order to obtain electron emission suitable for electron beam devices.

Experiments have shown that LaB6 has the lowest work function in the<100>crystal direction, resulting in the highest brightness. Therefore, it is required that the axis of the cathode rod should be consistent with this crystal orientation, with an error of ± 2 °.

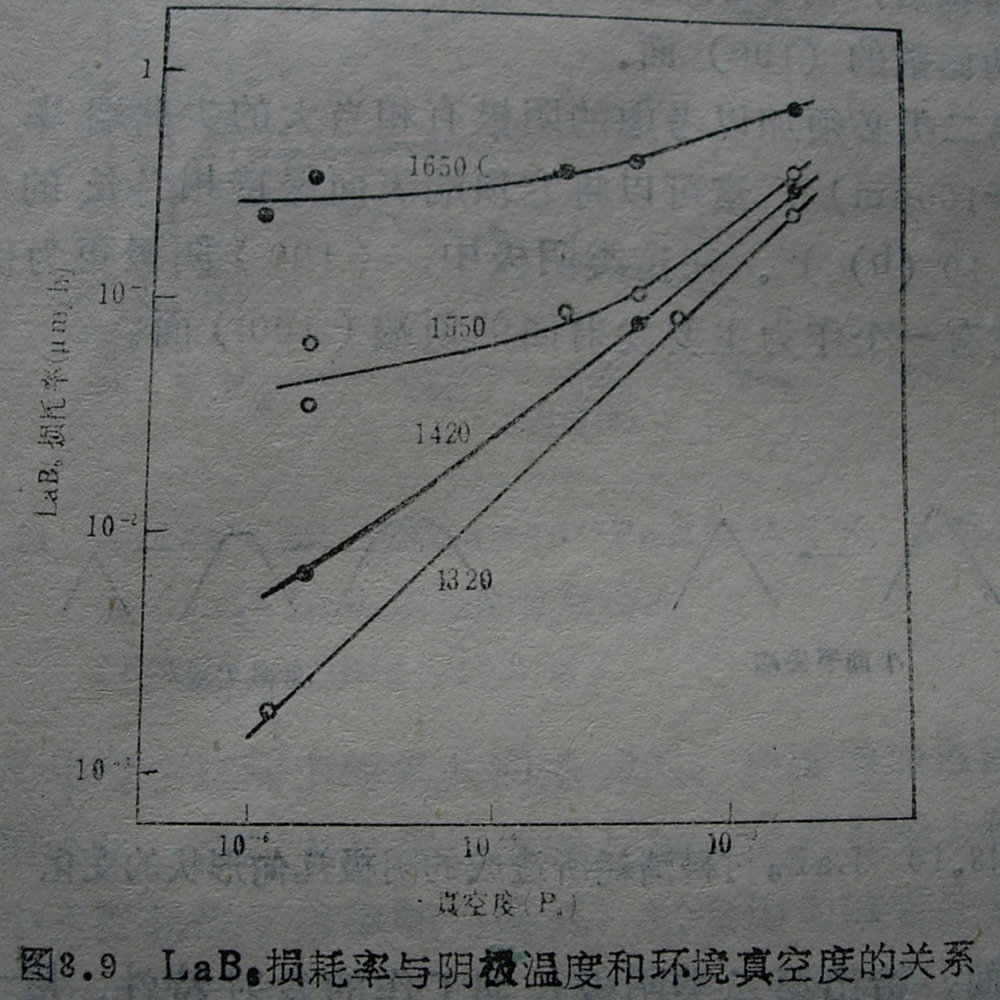

(3) Lifespan characteristics

The lifespan characteristics of LaB6 cathode, namely the emission performance during long-term operation, are mainly determined by the consumption of LaB6 material. The consumption of LaB6 is due to the thermal evaporation of the material, which increases with the increase of temperature and the deterioration of vacuum degree.