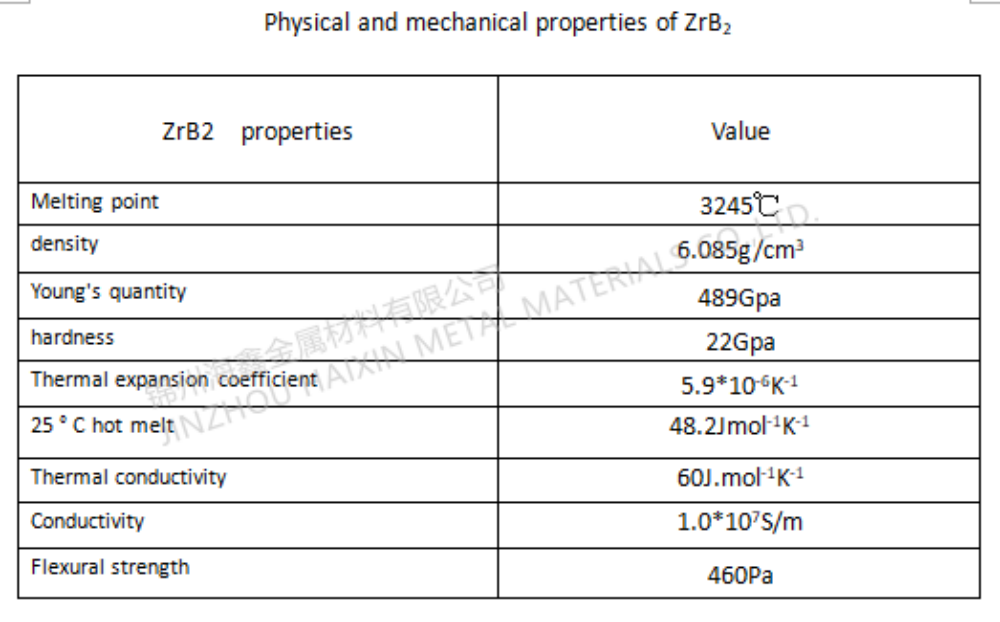

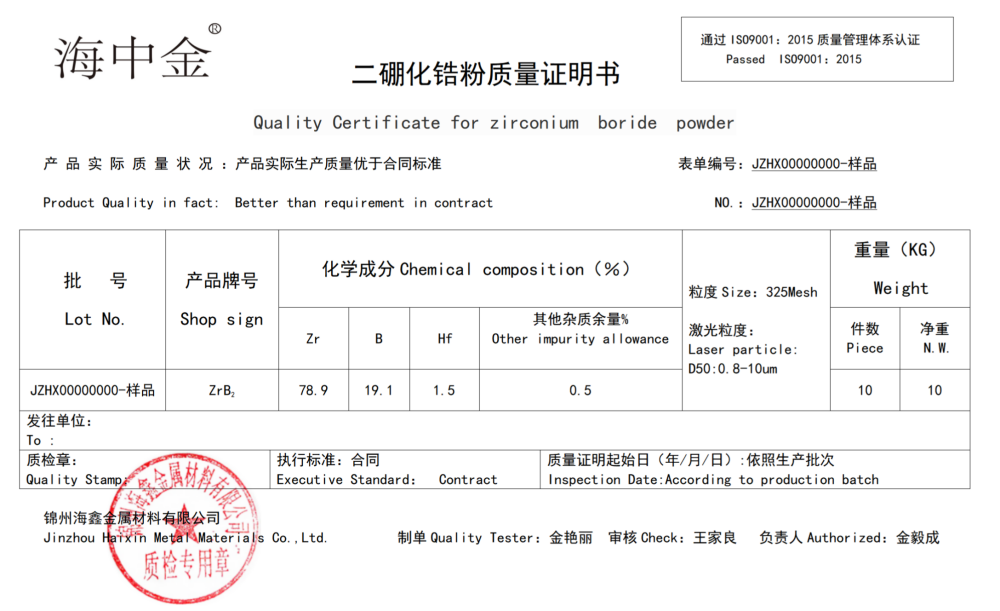

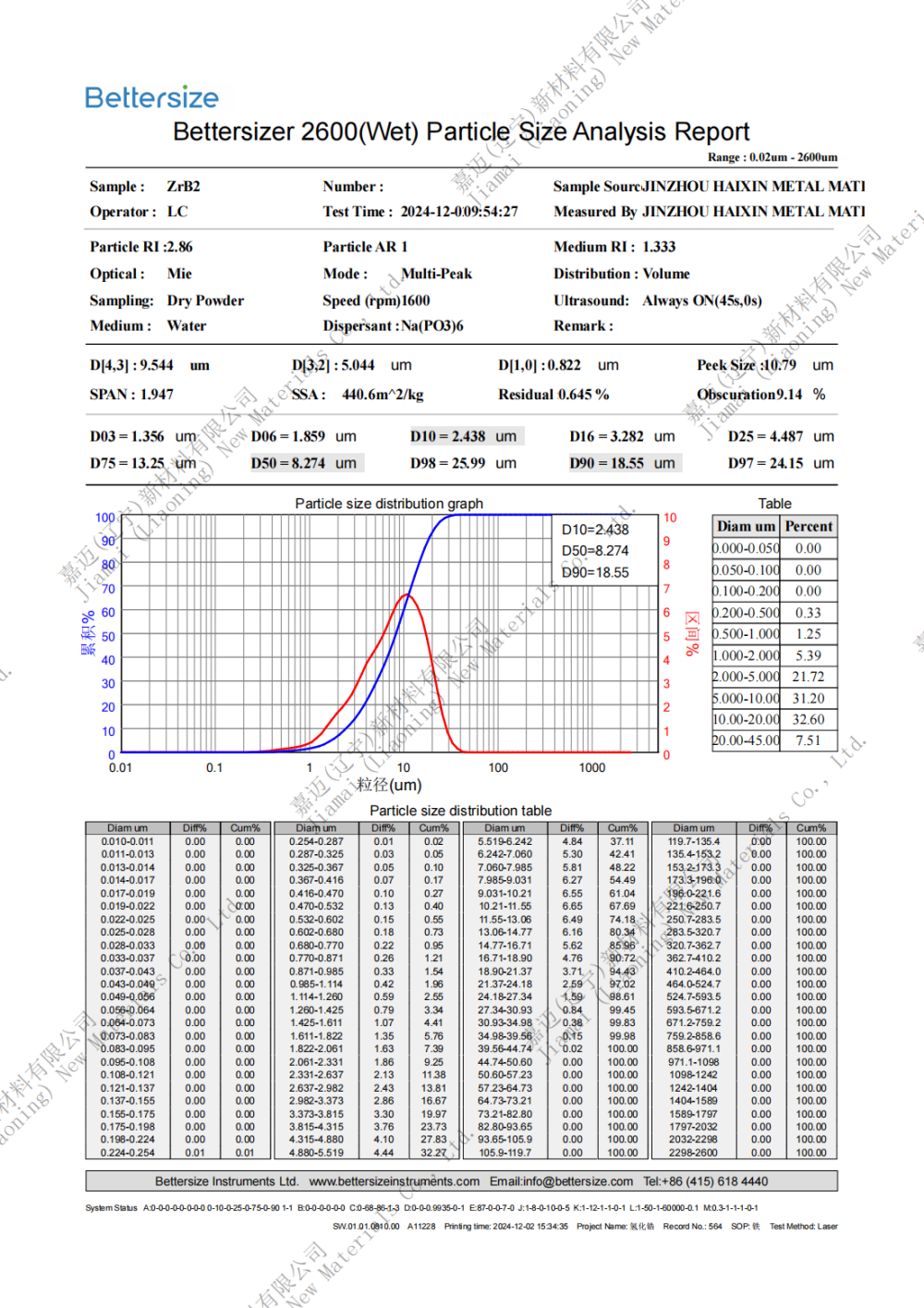

Product Name: Zirconium diboride (ZrB2)

Specification: 0.8-10um (D50)

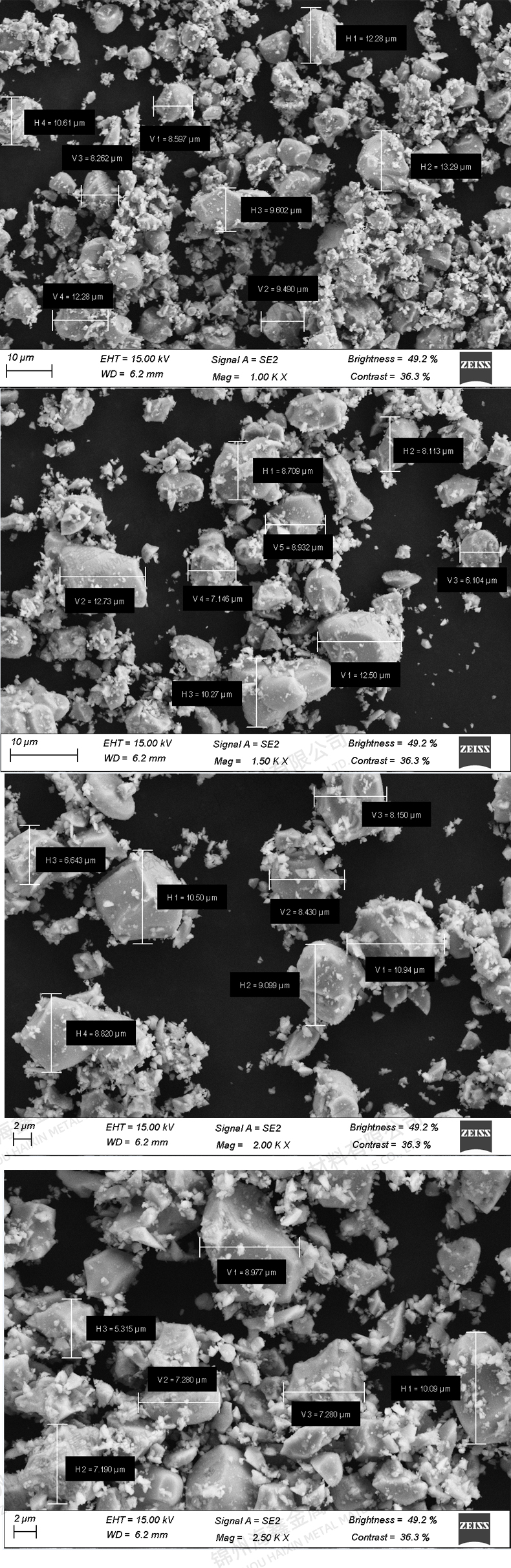

Appearance: Irregular

Color: Black Grey

Features: high melting point, high hardness, high stability, good electrical and thermal conductivity, oxidation resistance and chemical corrosion resistance, good radiation resistance, excellent ultra-high temperature thermal protection performance

Application: Nuclear waste treatment, microelectronics manufacturing, aerospace, as well as high-temperature, corrosive environments and other fields

Zirconium diboride

CAS No:12045-64-6

EINECS number: 234-963-5

Molecular formula: ZrB2

Molecular weight 112.84

Density 4.52g/cm3

Melting point 3040 ℃

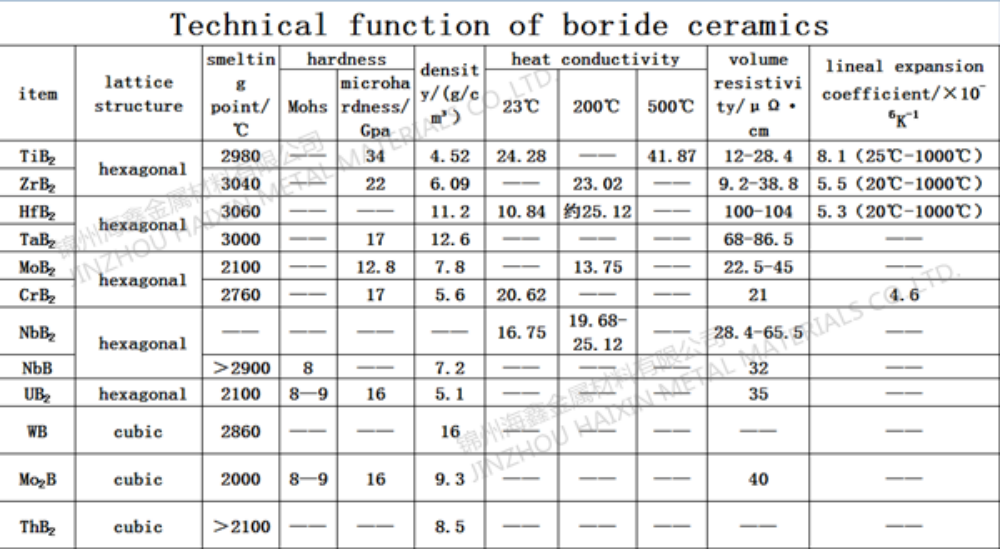

Zirconium boride is a common material in borides, and there are three types of zirconium borides in the boron zirconium system, namely zirconium diboride (ZrB), zirconium diboride (ZrB2), and zirconium dodecylboride (ZrB12). However, due to the good stability of zirconium diboride over a wide temperature range, most industrial produced zirconium borides are mainly composed of zirconium diboride.

1: Application Fields

1. Aerospace and Military Industry

ZrB2 composite materials are highly suitable as ultra-high temperature zero ablation materials for supersonic spacecraft and missile shells due to their high melting point, high hardness, good conductivity, and excellent neutron control capabilities. Especially with the rapid development of rocket and missile technology today, there is an urgent demand for high-temperature structural materials such as zirconium boride based ceramics. With the continuous deepening of research and development work and the continuous improvement of production technology, it can be affirmed that the research, production, and application of ZrB2 composite materials will make new strides forward.

Zirconium diboride (ZrB2) has become the most promising candidate material for ultra-high temperature ceramics due to its extremely strong chemical bonding properties, including high melting point, high modulus, high hardness, high thermal and electrical conductivity, and good thermal shock resistance. ZrB2 ceramic products have been widely used as various high-temperature structural and functional materials, such as turbine blades in the aviation industry, magnetic fluid power generation electrodes, etc. In addition, compared with many ceramic materials, it has better conductivity and can produce complex shaped components through wire cutting technology. However, ZrB2 material has a high melting point, difficult sintering, and relatively low strength and toughness, which limits its application in harsh working environments. Therefore, scholars at home and abroad have conducted extensive research on ZrB2 composite materials with the addition of other components using various advanced sintering processes to improve the overall performance of the materials. The author mainly reviewed the research work on ZrB2 composite material system and densification.

2. Refractory materials

ZrB2 ceramic is an excellent special refractory material that can be used as a high-temperature thermocouple protective sleeve, mold, crucible for metallurgical metals, etc. When used as a thermocouple protective sleeve, it has poor airtightness and conductivity. Therefore, it is necessary to cooperate with the aluminum oxide inner sleeve in order to carry out effective temperature measurement work. This material of thermocouple sleeve can be used continuously for a long time in molten iron or brass melt.

ZrB2 ceramics can also serve as antioxidants for refractory materials. Lv Chunyan et al. reported that adding ZrB2 to MgO-C refractory materials or directly using ZrB2 as aggregate or fine powder to make refractory bricks and castables has excellent antioxidant and refractory properties. The antioxidant mechanism can be analyzed as B2O3 generated by the oxidation of zirconium boride at medium temperatures forms MgO · B2O3 molten phase in MgO-C, thereby protecting the bricks.

3. Electrode material

ZrB2, due to its low resistivity and electronic conduction mechanism, is suitable for contact and electrode materials and can be used in electrodes of metal thermocouples and high-temperature heating elements. In 1994, Feng Dagang developed a sleeve type thermocouple material composed of ZrB2 and graphite. Experimental results showed that it can operate in an oxidizing atmosphere at temperatures ranging from 1200 to 1600 ℃, with a high thermoelectric potential value of around 70 mV at 1600 ℃ and a high thermoelectric potential rate of approximately 55 μ V/℃. The thermoelectric potential varies as a single value function with temperature, showing good linearity. After multiple tests in an oxidizing atmosphere, its repeatability ranges from 1% to 1.5% of the measured temperature. The maximum change in temperature during short-term continuous testing for more than 3 hours is 0.5% to 1% of the measured temperature. It can play a role in continuous temperature measurement in certain special occasions where metal thermocouples and radiation thermometers are not suitable, and is a good thermocouple material.

2: Preparation of zirconium diboride ceramic material

① Preparation of ZrB2 powder

The main method for producing ZrB2 powder is through the boronation reaction using zirconium or high oxides. The traditional synthesis method is to achieve the oxide carbon thermal reduction process in a high-temperature induction furnace or resistance furnace. This method has a simple process, but generally has a high temperature (around 1800 ℃), low purity of synthesized powder, large average particle size ratio, and poor sintering activity. Nowadays, carbon thermal reduction method, high-temperature self propagating method, mechanical alloying method, ceramic precursor cracking method, liquid-phase method, etc. are widely used.

② The Forming Method of ZrB2 Ceramics

There are many methods for forming ZrB2, such as isostatic pressing, dry pressing, injection molding, and solidification molding. People can choose different molding methods according to their own needs and actual conditions. In order to improve the density of the product and reduce the sintering temperature, people mostly use hot pressing sintering, which is a process of forming and sintering simultaneously, but can only obtain ZrB2 ceramic products with simple shapes.

③ Sintering method of ZrB2 ceramics

The traditional sintering methods for ZrB2 materials include pressureless sintering and hot pressing sintering, while new sintering methods include in-situ reaction hot pressing, high-temperature self propagating sintering, and discharge plasma sintering.

3、 Application examples of zirconium diboride ceramic materials

Zirconium diboride ceramics are highly valued and applied in high-temperature structural ceramic materials, composite materials, refractory materials, electrode materials, and nuclear control materials due to their high melting point and hardness, good electrical and thermal conductivity, and strong neutron control ability. For example, turbine blades and magnetic fluid power generation electrodes in the aviation industry. In addition, compared with many ceramic materials, it has better conductivity and can produce complex shaped components through wire cutting technology.

① Refractory materials

ZrB2 ceramic is an excellent special refractory material that can be used as a high-temperature thermocouple protective sleeve, mold, crucible for metallurgical metals, etc. When used as a thermocouple protective sleeve, it has poor airtightness and conductivity. Therefore, it is necessary to cooperate with the aluminum oxide inner sleeve in order to carry out effective temperature measurement work. This material of thermocouple sleeve can be used continuously for a long time in molten iron or brass melt. ZrB2 ceramics can also serve as antioxidants for refractory materials.

② Electrode material

ZrB2, due to its low resistivity and electronic conduction mechanism, is suitable for electric shock materials and electrode materials, and can be used in electrodes of metal thermocouples and high-temperature heating elements. In 1994, researchers developed a sleeve type thermocouple material that pairs ZrB2 and graphite. Experimental results showed that it can work in an oxidizing atmosphere at 1200-1600 ℃, with a high thermocouple value of around 70mV at 1600 ℃ and a high thermoelectric potential. It can play a role in continuous temperature measurement in certain special occasions where metal thermocouples and radiation thermometers are not suitable, and is a good thermocouple material.

③ Other materials

Due to its extremely high hardness, ZrB2 is an excellent wear-resistant material and has good applications in cutting tools and cutting tools. ZrB2 has been extensively studied abroad for its excellent corrosion resistance and anti-oxidation properties.