Product Name: Zirconium Iron (ZrFe)

Specifications: 100 mesh, 200 mesh, 325 mesh

Appearance: Irregular

Color: Silver Grey

Features: Excellent wear resistance and strength

Usage: Deoxidizer and alloying agent in steelmaking industry, inoculant and spheroidizing agent in cast iron industry, reducing agent in ferroalloy production, etc

Name: Zirconium Iron

Molecular formula: FeZr

Cas:12023-45-9

Appearance: Silver gray

Melting point: 1852 ℃

Boiling point: 4400 ℃

Density: 6.49g/cm3

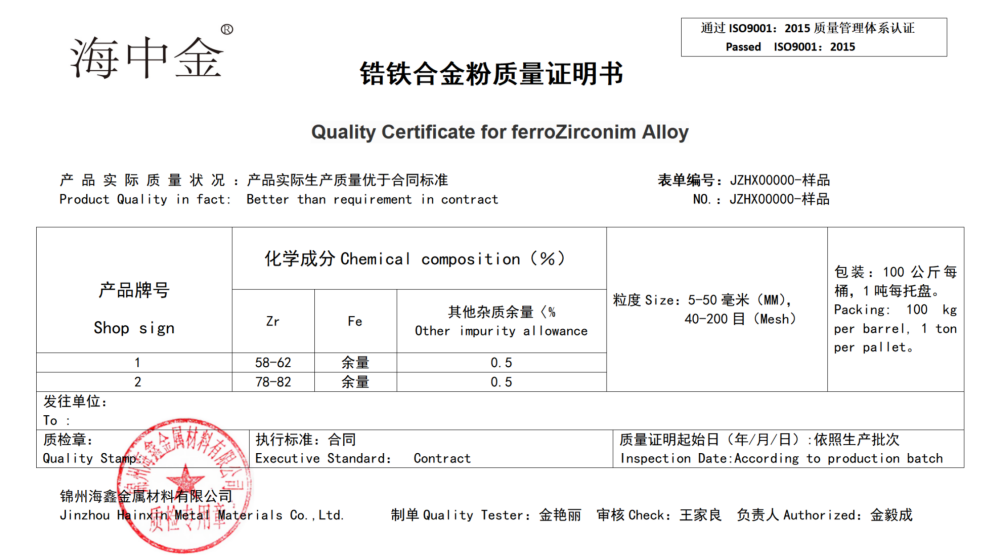

Particle size: 5-50mm

Packaging: 100kg/drum

Zirconium iron is an iron alloy composed of zirconium, iron, silicon, aluminum and other elements. The zirconium iron used in steelmaking is zirconium ferrosilicon, containing 15% to 45% Zr and 30% to 65% Si. The products produced by aluminum thermal method are called zirconium iron due to their aluminum content, with Zr content greater than 15%. Zirconium and iron form a stable compound FeZr2 (45.1% Zr) with a melting point of 1650 ℃. There are two co crystals in the Fe Zr system. At 16% Zr, the eutectic melting point is 1330 ℃; At 84% Zr, the eutectic melting point is approximately 940 ℃. Zirconium iron is used as a deoxidizer and alloy additive in high-temperature alloys, low-alloy high-strength steels, ultra high strength steels, and cast iron for special purposes, and is subsequently used in atomic technology, aviation manufacturing, radio technology, etc.