Product Name: Zirconium Copper (ZrCu)

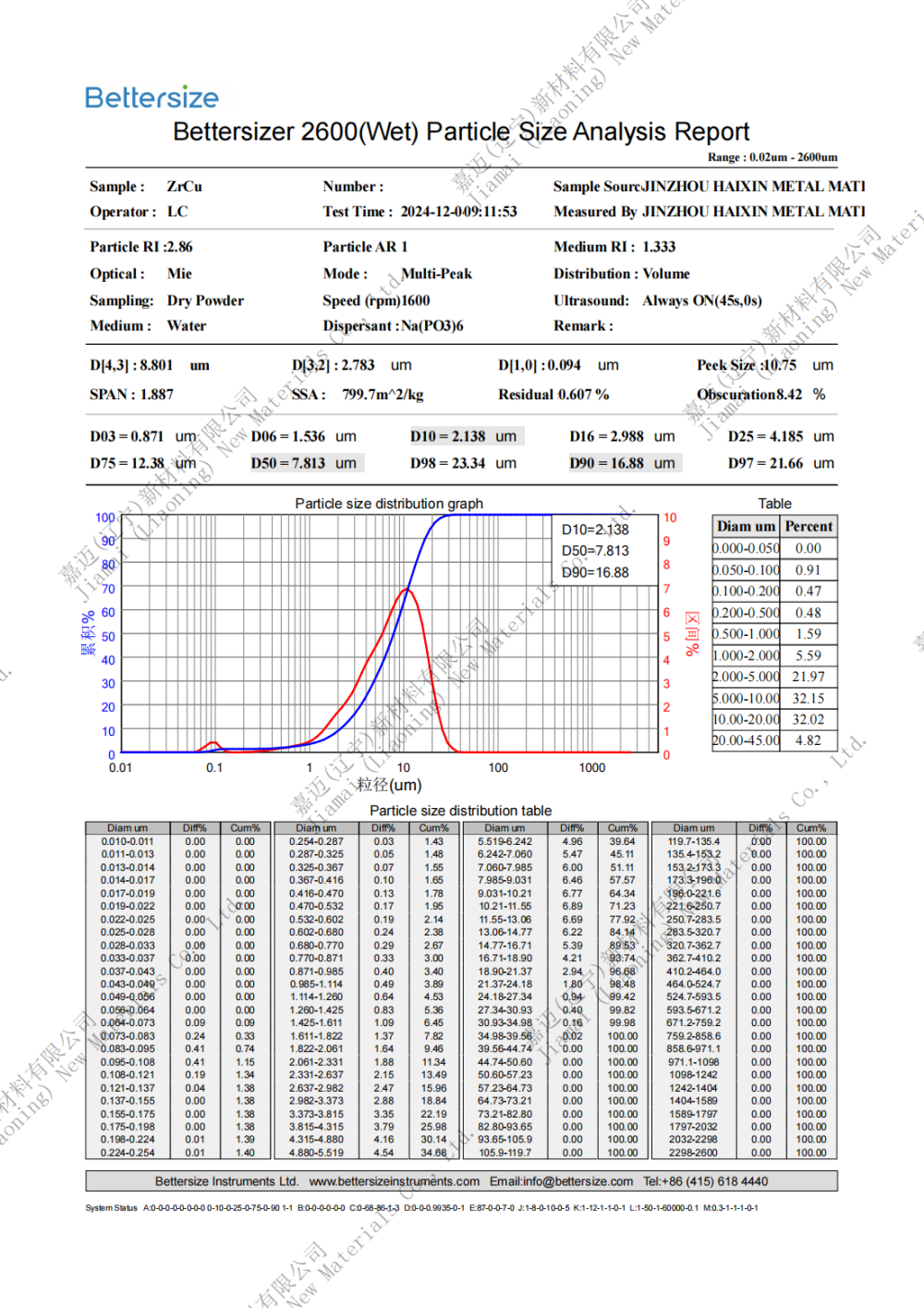

Specifications: 100 mesh, 200 mesh, 325 mesh or block

Appearance: Irregular

Color: Metallic

Characteristics: Zirconium copper has good electrical conductivity, thermal conductivity, high hardness, wear resistance, explosion resistance, crack resistance, and high softening temperature.

Usage: Used for ICs with excellent performance, for various types of lead frames, high-power switches, relays, and other electronic components.

Zirconium copper alloy

Density 8.89 g/cm3

Melting point 980 ° C

Zirconium copper alloy is not only used for discrete packaging of small signal transistors or power transistors, but also for ICs with excellent performance, used for various types of lead frames, high-power switches, relays and other electronic components. CuZr alloy has high heat resistance and softening resistance by adding Zr to high-purity oxygen free copper. Therefore, utilizing the superior properties of oxygen free copper, it has attracted much attention as a non electroplated lead frame material.

Zirconium copper alloy is a preferred material for circuit contacts and other applications due to its excellent electrical and thermal conductivity. If the switch contacts disconnect the circuit, the generated arc will exert a considerable load on the material, which is precisely the effect of high-temperature resistant chromium. Chromium can improve the arc erosion resistance of materials, have good resistance to welding, and prevent soft copper parts from sticking to each other during welding. Chromium also has high oxygen affinity and can absorb the oxygen released during the breaking process.

Purpose: Suitable for producing resistance welding caps