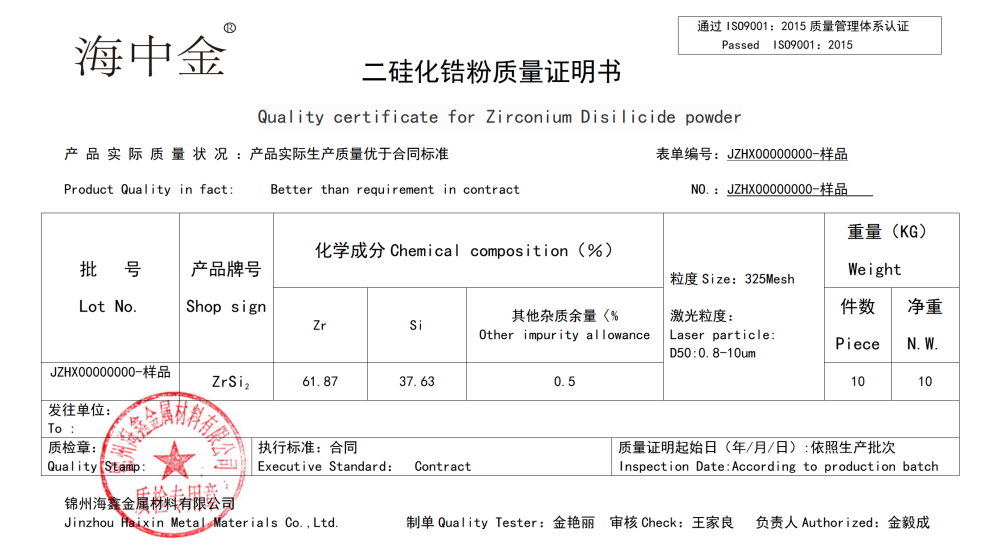

Product Name: Zirconium Disilicide (ZrSi2)

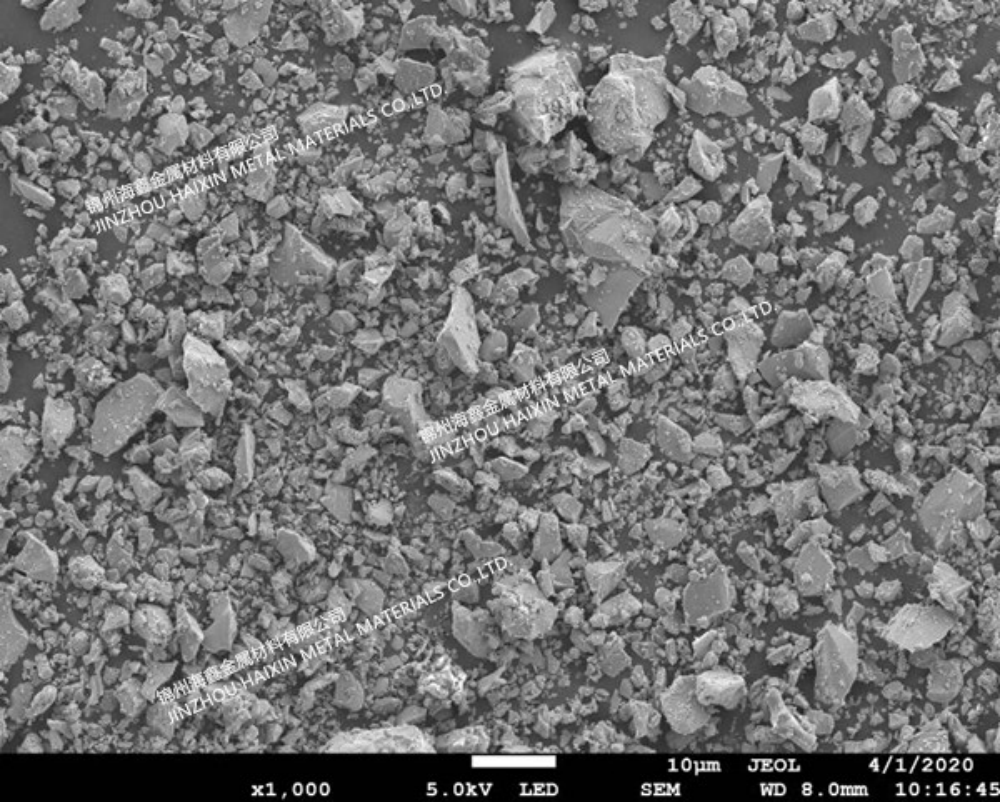

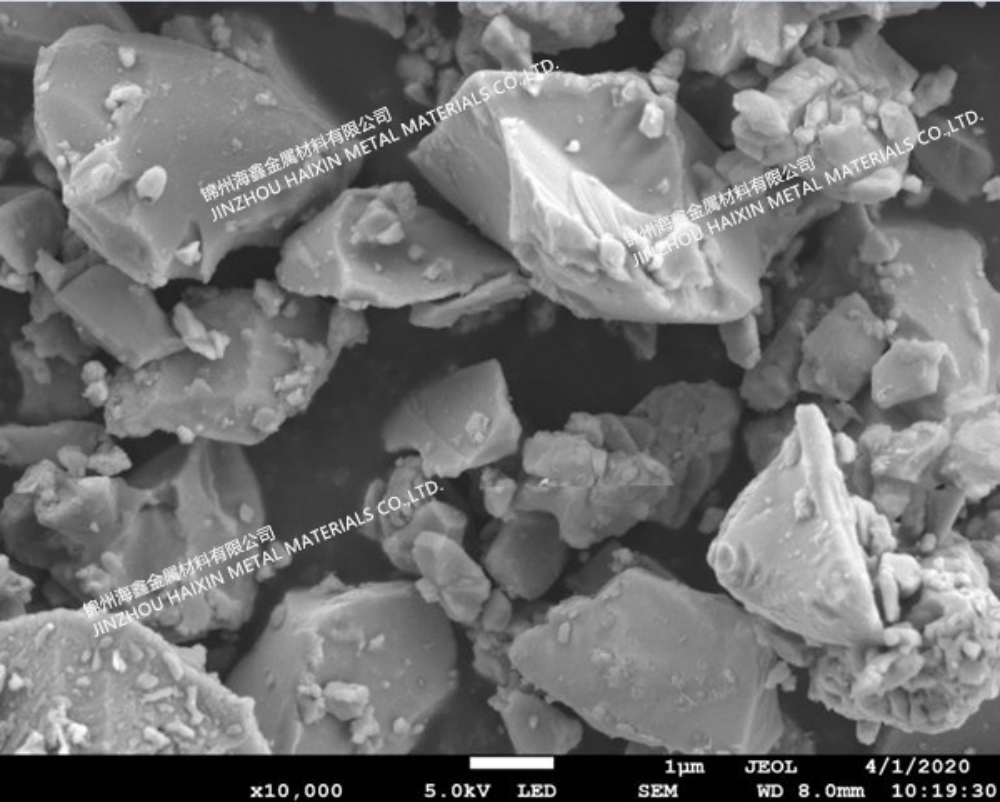

Specification: 0.8-10um (D50)

Appearance: Irregular

Color: Black Grey

Features: high hardness, high melting point, high conductivity, high thermal conductivity, and excellent thermal shock resistance

Usage: High tech fields such as information and communication, aerospace, military, coatings, inks, rubber and plastic, ceramics, textiles, cosmetics, pharmaceuticals, batteries, environmental protection, solar energy, etc

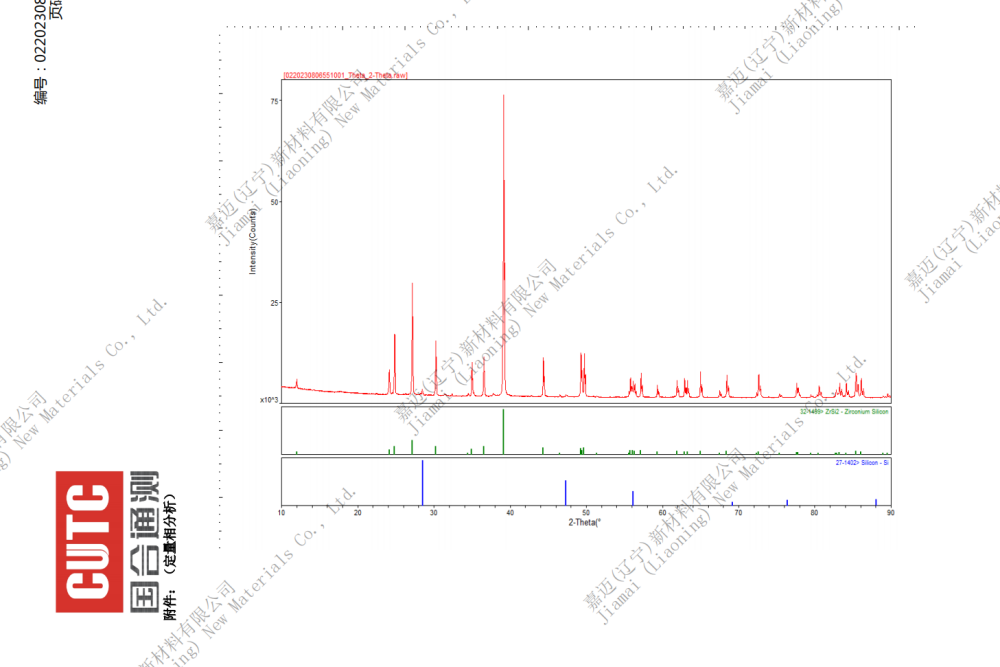

Zirconium silicide

chemical formula: ZrSi2

CAS Number: 12039-90-6

Molecular weight: one hundred and forty-seven point four

Appearance: Grey square crystalline powder

Density (g/mL, 25 ℃): 4.88

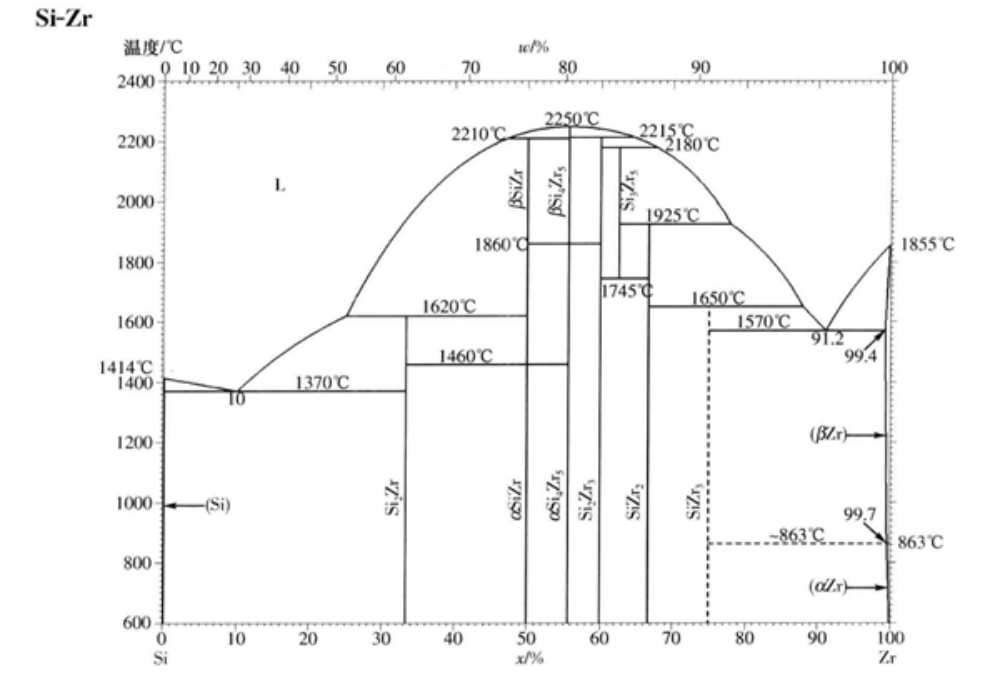

Melting point (oC): 1620

Lattice constant: a=0.372nm,b=1.476nm,c=0.367nm。

Microhardness (kg/mm2): 1063

Heat of generation (kJ/mol): 62.8

Property: Zirconium silicide or zirconium disilicide, chemical formula ZrSi2, is a steel gray diamond shaped glossy crystal with a relative density of 4.8822. Zirconium silicide is insoluble in water, inorganic acids, and aqua regia, but soluble in hydrofluoric acid.

Preparation process of zirconium silicide: Zirconium silicide is prepared from metal zirconium and silicon powder as raw materials. Firstly, zirconium metal is crushed, and then thoroughly mixed with silicon powder. The mixture is placed in a graphite furnace and heated to 900-1000 ℃ for pre reaction. Then, hydrogen gas is introduced and heated to around 1200 ℃ for homogenization reaction to obtain zirconium silicide.

Main purpose:

1. High temperature structural materials and coatings

Application: Gas turbine blades, rocket engine nozzles, high-temperature furnace components.

Basis: Zirconium silicide has a high melting point (about 2200 ° C), excellent high-temperature oxidation resistance, and thermal stability, making it suitable for structural support in extreme environments or as a protective coating to reduce thermal corrosion of the substrate material.

2. Semiconductors and Electronic Devices

Application: Contact layer and diffusion barrier layer in integrated circuits.

Basis: It has good compatibility with silicon substrates, high conductivity, and may be used to reduce contact resistance, especially in high-temperature or high-power devices (compared to titanium/cobalt silicide, there is less research but potential).

3. Nuclear industry materials

Application: Protective coatings or structural components for nuclear reactors.

Basis: Zirconium has a small neutron absorption cross section, and zirconium silicide may be used for neutron reflection layers or radiation resistant environments, but further verification of practical application cases is needed.

4. Wear resistant and protective coatings

Application: Surface coating for cutting tools and molds, anti-corrosion layer for aviation components.

Basis: High hardness and wear resistance can extend tool life, and coating technology (such as CVD) enhances the substrate's wear resistance.

5. Thermoelectric materials

Application: Waste heat recovery power generation system, thermoelectric generator.

Basis: Some zirconium silicide compounds have high thermoelectric figure of merit (ZT), which can convert thermal energy into electrical energy and are suitable for industrial waste heat utilization.

6. Composite material reinforcement phase

Application: Ceramic based or metal based composite materials.

Basis: High temperature strength and toughness as enhancing materials, such as spacecraft thermal protection systems.

7. Exploration of emerging fields

New energy: research as electrode materials or catalyst carriers for lithium-ion batteries.

Coating technology: Develop new anti-oxidation coatings for use in automotive exhaust systems or chemical equipment.

Packaging and storage: This product is packaged in an inert gas filled plastic bag, sealed and stored in a dry and cool environment. It should not be exposed to air to prevent moisture from causing oxidation and aggregation, which may affect dispersion performance and usage effectiveness; The packaging quantity can be provided in separate packages according to customer requirements.